Open Source Hardware

Open source hardware (OSH) refers to physical products such as machines, tools, or devices whose design plans, technical documentation, and associated production knowledge are openly accessible. This information can be used, adapted, reproduced, and further developed. OSH differs from proprietary hardware in that it discloses technical fundamentals and uses standardized open licenses.

The openness of hardware is discussed in research and practice as a prerequisite for decentralized production structures, collaborative development processes, and traceable value creation. At the New Production Institute (NPI), open source hardware forms a point of reference for research and testing in the context of production, digitization, and urban spaces. OSH is investigated and further developed in experimental, application-oriented, and scientific formats.

Intro

OSH promotes technologies for a new type of production

- Openness as a principle of new value creation: OSH embodies the principle of openness, which we systematically operationalize for new forms of production.

- Decentralization & resilience: Open designs allow production technologies to be reproduced locally, independently of global supply chains.

- Participation & Innovation: OSH enables diverse stakeholders—from communities to companies—to participate in product development.

- Sustainability & circular economy: Openness promotes repairability, adaptability, and thus resource-saving product life cycles.

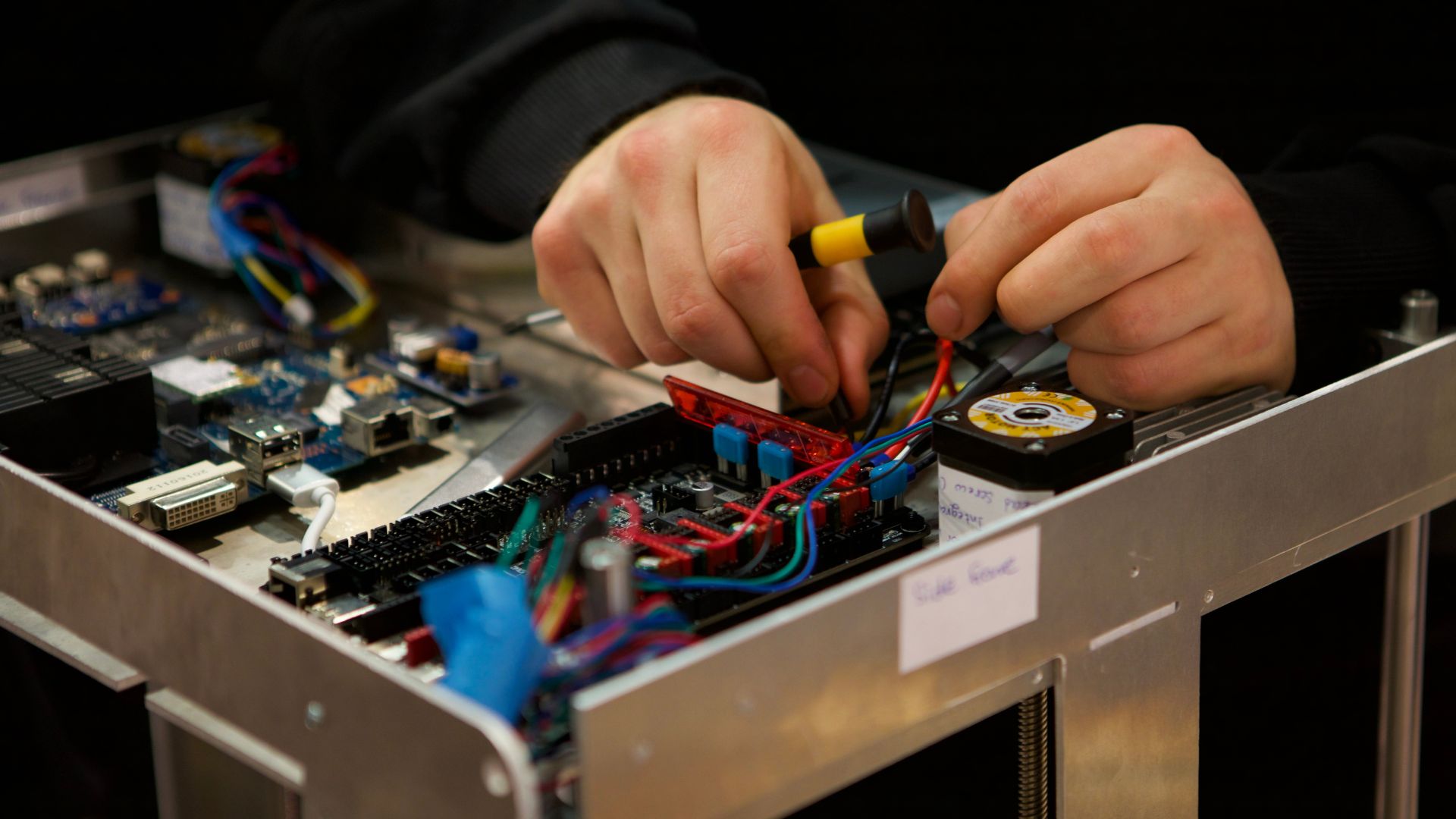

Media

OpenLab Starter Kit

Our approaches in the field of open source

At the New Production Institute, open source hardware is applied, researched, and further developed in various research, development, and transfer projects. The following examples provide an overview of key projects and documented work directly related to open source hardware.

Hamburg as Germany's first Fab City

In June 2019, the Free and Hanseatic City of Hamburg joined the global Fab Cities initiative, which aims to transform urban spaces into data-driven circular economies with digitally networked manufacturing infrastructure. In this model, material goods are to be produced locally and only digital construction plans are to be imported or exported.

The New Production Institute supports this approach by developing and testing publicly accessible production technologies in Fab Labs and OpenLabs. OpenLab Hamburg, which opened in December 2016 at Helmut Schmidt University, was inspired by the Fab Lab movement and offers public access to digital manufacturing technologies such as 3D printers, laser cutters, and milling machines.

Since 2022, eight additional OpenLabs with different thematic focuses have been established as part of the dtec.bw research project Fab City. These facilities serve as experimental infrastructure in which machine-based open source hardware is deployed, utilized, and further developed.

Fab Labs and OpenLabs function as open technology workshops and address technical, social, and environmental aspects of digital production. Typical machines include digital manufacturing tools (e.g., 3D printers, CNC milling machines, laser cutters) and complementary workshop equipment.

Urban Production

The dtec.bw research project Fab City investigates open source hardware approaches as part of urban production systems. The OpenLabs created as part of the project serve as experimental research and development environments for open production systems. Open source machine tools are used, further developed, and documented in these real-world laboratories. They form an infrastructural and empirical basis for local manufacturing, experimental production processes, the exchange of digital production data, and research into decentralized manufacturing, qualification, governance, and knowledge exchange.

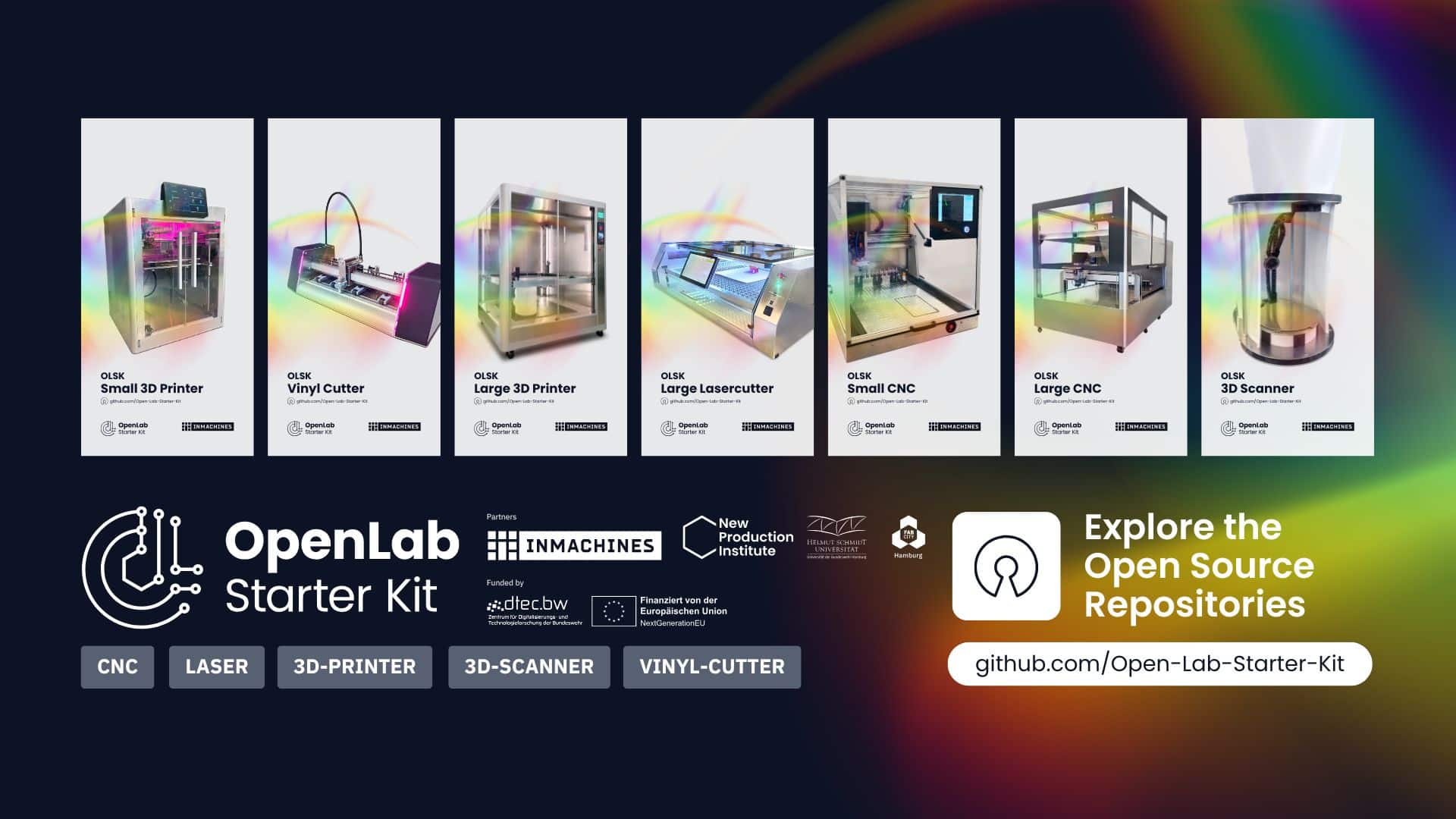

An open-source set of machines for Fab Labs

The Open Lab Starter Kit (OLSK) is a modular set of open digital manufacturing machines for use in Fab(rication) Labs, OpenLabs, or mobile makerspaces, for example. All designs, construction plans, and instructions are openly accessible and can be reproduced worldwide.

Overview

Objective

The project is primarily aimed at makers, educational institutions, and professional fab labs or makerspaces. In addition to this primary goal, alternative applications for the OLSK have already been investigated, for example in small and micro-enterprises in developing regions. These micro-enterprises have the potential to significantly increase their production through expanded access to digital manufacturing. The project thus goes beyond classic maker requirements.

The OLSK aims to provide a repository-based set of open source machines that can be reproduced locally and cost-effectively. The goal is to make global knowledge available for local production and to close the gap between commercial and open source machines. The project also addresses barriers to accessing digital manufacturing technology (inmachines.net). Außerdem adressiert das Projekt die Barrieren beim Zugang zu digitaler Fertigungstechnologie (inmachines.net).

Development Approach

Development took place in three consecutive, one-year iterations. Each phase included:

- Design, construction, and intensive testing of a prototype of each machine

- Continuous development based on experience from previous cycles

- Public build workshops where replicability and usability were tested

Each development phase was comprehensively documented and published in a publicly accessible design repository. The assembly instructions were continuously improved to ensure global reproducibility.

Significance for Research and Practice

Doctoral Theses and Puclications

- Omer, M., Kaiser, M., Ingrassia, D., Redlich, T., Moritz, M., Wulfsberg, J. „Inclusive Production Capacity Building for MSMEs: Designing Open Source Machine Tools and the OLSK Approach.“ Procedia CIRP 128 (2024): 758–763 (DOI).

Funding and Contact Person

- The OLSK is part of the dtec.bw Fab City project at the Laboratory of Production Engineering at Helmut Schmidt University in cooperation with Inmachines and will run from 2022 to 2026. The project is supported by dtec.bw and financed by the European Union – NextGenerationEU.

- Contacts are: Dr.-Ing. Tobias Redlich, Dr.-Ing. Manuel Moritz, Daniele Ingrassia, Mohammed Omer und J.C. Mariscal-Melgar.

Basic learning modules for open source and open education

The GitHub repository “Basislernmodule-Fab-Labs” provides a collection of learning modules on the use of Fab Labs as Open Educational Resources (OER). These modules were developed to teach basic topics in digital manufacturing and the use of open workshops (“Fab Labs”), including 3D design, 3D scanning, 3D printing, laser cutting, and CNC milling.

The content aims to spark interest in digital manufacturing technologies, highlight potential applications, and impart basic knowledge without limiting itself to device-specific details; rather, it serves as preparation for practical workshops and further learning activities in open workshops. Publication as OER under an open license promotes free access, reusability, and collaborative further development of the learning materials.

International practical laboratories and transfer projects

- INTERFACER combines open source software and hardware with digital tools such as product passports and data platforms. The aim is to investigate circular and local production processes in Fab City contexts.

- Production Next Door (ProNeD)

ProNeD researches decentralized production networks in which open source hardware plays a central role in local manufacturing and global knowledge circulation. - Digital4Jobs / OpenLab Tunis

OpenLabs with open source hardware machines have been set up and used as part of international collaborations. The focus is on training, local adaptation of open machines, and empirical research on usage contexts. - Places of Incubovation / PISWI

The project investigates open production infrastructures and open source hardware in the context of social and economic development processes, particularly in North African cities.

Application examples of open source hardware

- The ideas competition for Hamburg: The Maker Challenge 2026

- LOCILAMP – The Fab City Lamp

- Deep Tech & Hardtech Innovation Hub | MotionLab.Berlin

- Tolocar – Mobile makerspace in Ukraine

- OpenLab Mobile for Hamburg and the metropolitan region

- OpenLab MedTech at the Bundeswehr Hospital in Hamburg

OpenLab Microfactory

The OpenLab Microfactory is a modular production environment that bundles open source hardware machines in an integrated manufacturing context. It is used to investigate local production processes, data acquisition, and the scalability of open manufacturing infrastructures.