Your product. Globally designed. Locally produced.

Production Next Door was a real-world laboratory for local, networked, and sustainable production in Hamburg. The project brought together research, civil society, and business to test new forms of urban manufacturing. The aim was to make urban production more ecological, socially equitable, and technologically innovative, and to actively involve citizens in the design process.

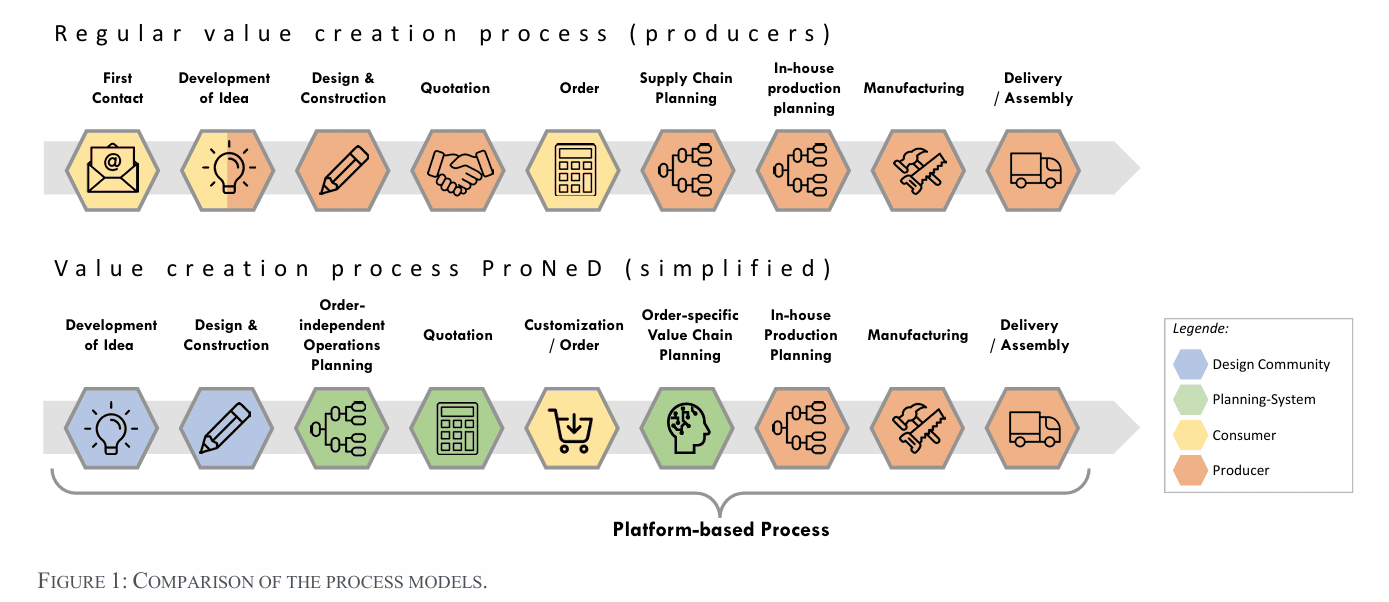

The research project investigated how a sustainable, digitally supported value creation process for urban spaces can be designed can be produced – according to the principle of “globally designed, locally manufactured.” The aim was to develop an infrastructure that intelligently combines global product development, local manufacturing, and individual use.

The interdisciplinary research team led by Dr. Pascal Krenz at the Manufacturing Technology Laboratory at Helmut Schmidt University developed and tested concepts for distributed production in cities: Digital technologies were transferred to urban value creation networks, in particular methods from Industry 4.0, machine learning, and data mining.

The focus was on issues relating to the planning and control of decentralized, dynamic production processes, the use of self-learning systems, and the potential for a sustainable circular economy—through shorter transport routes, transparent material flows, and resource-efficient production.

A key element was the publicly advertised ideas competition For Future Furniture, which offered people interested in furniture and design the opportunity to realize their ideas—with the prospect of sharing in subsequent sales proceeds. The award-winning designs were implemented exclusively by local carpentry businesses. In this way, the project not only promoted creative participation, but also regional value creation and sustainable consumption.

The project was supported by HITeC e.V. in the field of artificial intelligence and by UNITY AG in the development of strategic and business model-related approaches for digital platform solutions.

For Future Furniture

Production next door – your product. Globally designed. Locally produced.

- Competition for local furniture production to improve control and transparency along the value chain

- Implementation of the winning designs by local carpenters to strengthen regional economic cycles

- Promoting sustainable consumption through locally produced, durable, and repairable furniture

- Testing new tools, formats, and infrastructures for urban production

Competition impressions

Artiko – The invisible home office solution: A modular home office space. The desk with stool is concealed in the sideboard/Johannes Müller (Studiojm).

Side table – swipe is an innovative side table that combines traditional bentwood technology with today’s modern design language in a unique symbiosis / Bernd Görtz.

CUBIC table. One table. Six seats. More space. A minimalist table that fits into any home yet stands out thanks to its graphic design. Six stools that can be quickly and easily stored under the tabletop and pulled out as needed / Team Lasse Bork.

Award ceremony for the For Future Furniture design competition at the future of making Conf + Expo 2023. Photo credits: CC BY-SA 4.0 interfacer.eu / Dawid Jakubowski

“The Overlap is a side table and storage unit in one. At the heart of the piece are two cubes at the base that support the tabletop and provide storage space for various everyday items.” – Deniz Aktay

Photo Credits: CC BY-SA 4.0 interfacer.eu / Dawid Jakubowski

Photo Credits: CC BY-SA 4.0 interfacer.eu / Dawid Jakubowski

“MODIFY will be with you for a long time. The simple bed frame can be customized to your personal taste with a selection of different surfaces and materials. The width can be adjusted by replacing the end panels, and the easily interchangeable legs allow for variable heights. The freely combinable headboards offer further options for individualization, and their covers can be removed and replaced.” – Steffi Seitz

Photo Credits: CC BY-SA 4.0 interfacer.eu / Dawid Jakubowski

Photo Credits: CC BY-SA 4.0 interfacer.eu / Dawid Jakubowski

Photo Credits: CC BY-SA 4.0 interfacer.eu / Dawid Jakubowski

“Midiklapp is a room divider that offers more—a shelf, workspaces, and a place to rest. All this in a simple and minimalist design.”—Lisa Wiesgickl

Photo Credits: CC BY-SA 4.0 interfacer.eu / Dawid Jakubowski

Die im Rahmen des dtec.bw Fab City-Projekts entwickelten Produktionstechnologien sollen durch eine offene Projektdokumentation weltweit zugänglich gemacht werden, durch Selbstreplikation und modulare Bauweise eine maximale Skalierung und Verbreitung ermöglichen und durch den entsprechenden Designansatz nur minimale Kosten erfordern. Der Wissenstransfer soll in Form von projektbezogenen (Bau-)Workshops in Fab Labs oder Open Labs erfolgen. Die Skalierung wird durch das Train-the-Trainer-Prinzip und eine offene Dokumentation gewährleistet, die ein ganzheitliches Themenspektrum von der Produktidee bis zum Geschäftsmodell abdeckt.

The associated issues are the subject of various fields of research, such as engineering, economics, law, social sciences, education, logistics, blockchain technology, and urban planning. In this project, an interdisciplinary research team will therefore investigate new theoretical foundations for decentralized digital and networked urban value creation. The findings derived from this research will offer society the opportunity for global product development and local manufacturing combined with new, individualized, and sustainable formats for innovation, production, and education. The project will be implemented in collaboration with local stakeholders and research partners in Hamburg (Fab City Hamburg).

For Future Furniture Competition

Fils Table Modules

The Flis table modules by Jonas Finkeldei are a modular table system that impresses with its static effect and flexible implementation. Table legs and table tops are connected by detachable semi-finished connectors, which makes assembly and disassembly easy. This design promotes local production and supports a sustainable circular economy by using resource-saving materials and minimizing transport distances.

For Future Furniture Competition

Award Ceremony

At the the future of making Conference + Expo on March 4, 2023, as part of the EU project INTERFACER, the winners of the direct prizes were announced and the 10 finalists were presented to the public.

Local value creation

The unpredictable occurrence of a global pandemic or escalating trade conflicts today show us the fragility of global, division-of-labor-based industrial value creation. The promotion of local value creation structures has numerous potentials for meeting current ecological, economic, and social challenges (strengthening the resilience of the manufacturing industry, reducing greenhouse gases, empowering regional companies and people).

Circular Economy

The Production Next Door project aimed to contribute to a sustainable circular economy by promoting local value creation structures.

Specifically, the project pursued the following objectives:

- Empowering regional players through new roles in development, design, and manufacturing

- Cost-effective, demand-driven manufacturing of customized products

- Reduction of emissions and resource consumption by avoiding transport routes and overproduction

- Provision of a wide variety of licensable, openly available product models through the integration of global developer communities

- Strengthening the resilience of the manufacturing industry by establishing regional production structures

To this end, methods and technologies from the fields of Industry 4.0, machine learning, and data mining were applied to the context of regional production. The aim was to establish a fully digitized value creation process that efficiently connects global online communities in product development, local producers in manufacturing, and end customers in customization in order to minimize friction losses along the entire value chain.

Further information

Bottom-up economy

Globalization and increasing digital networking are leading to completely new patterns of value creation. One model can be summarized under the term bottom-up economy. It differs from traditional economic systems in that it combines production and consumption and features distributed structures and processes for service provision. The bottom-up economy is based on a logic of openness and participation.

In some industries, a paradigm shift away from traditional company-centered, top-down value creation toward more open and collaborative bottom-up concepts can already be observed.

Right to Repair

Nowadays, products are rarely repaired:

– because they were not designed for this purpose

– because users lack the knowledge to repair them – because a new product is cheaper.

Repairing items can make a significant contribution to climate protection and resource conservation, promote the local economy, and create jobs.

The Ecodesign Directive, which has been in force in the EU since March 2021, regulates the reparability of individual product groups for the first time. For example, large electrical appliances such as refrigerators, washing machines, and televisions must be easier to repair and have a longer repair life. According to this new directive, refrigerators must be repairable for up to seven years and washing machines for up to ten years. Repairs must be possible using standard tools and (in certain cases) by the user themselves.