Testing local, circular, and distributed production

Global challenges such as resource scarcity, rising CO₂ emissions, and fragile supply chains require new forms of sustainable value creation.

The DATIpilot project LOCILAMP, funded by the Federal Ministry of Research, Technology and Space is a practical example of local, circular, and distributed production that tests scalable and participatory models for a post-industrial production logic. It examines how design, manufacturing, and data infrastructure can be implemented locally on an open-source basis—with the involvement of citizens, business, and research.

Mit der LOCILAMP (The Fab City Lamp) wurde ein wegweisender Prozess zur Entwicklung und Fertigung einer kreislauffähigen Leuchte etabliert. Die erste Iteration, Shift-Light, entstand im Rahmen des EU-geförderten INTERFACER Projekts als modulares Leuchtobjekt, dessen Gestaltung auf den Prinzipien der Kreislaufwirtschaft basiert: Modularität, Wiederverwendbarkeit, Reparierbarkeit und Suffizienz.

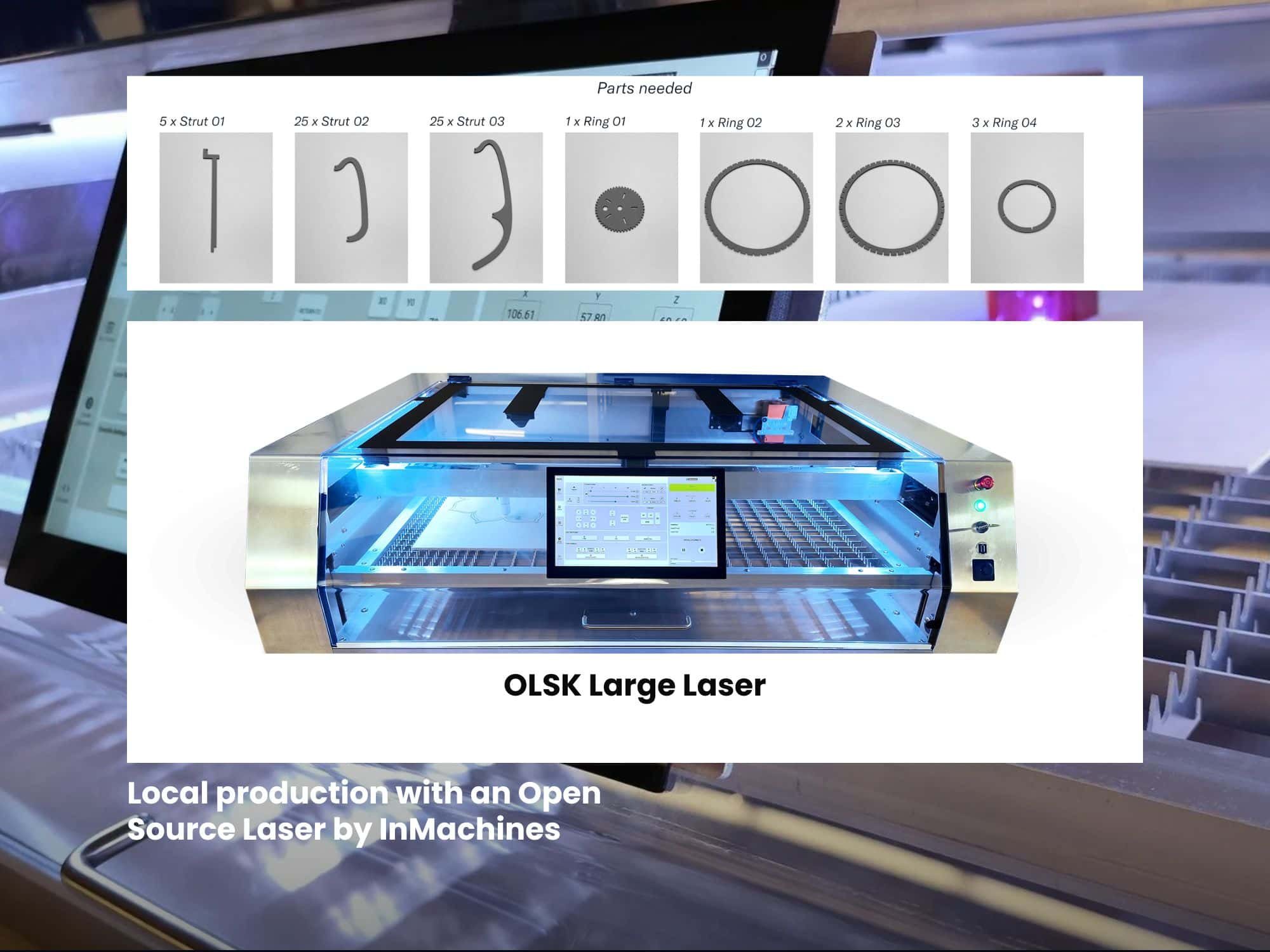

The name is derived from the Latin word “loci” – ‘places’ or “locations.” In mathematics, a locus (plural: loci) is the set of all points that satisfy a certain condition. LOCILAMP stands for production in different locations, connected by common principles. The lamp is not produced and shipped centrally, but manufactured at many locations – in FabLabs, workshops, and communities. The open-source design is shared digitally worldwide, while materials and manufacturing remain local. Local production. Global knowledge.

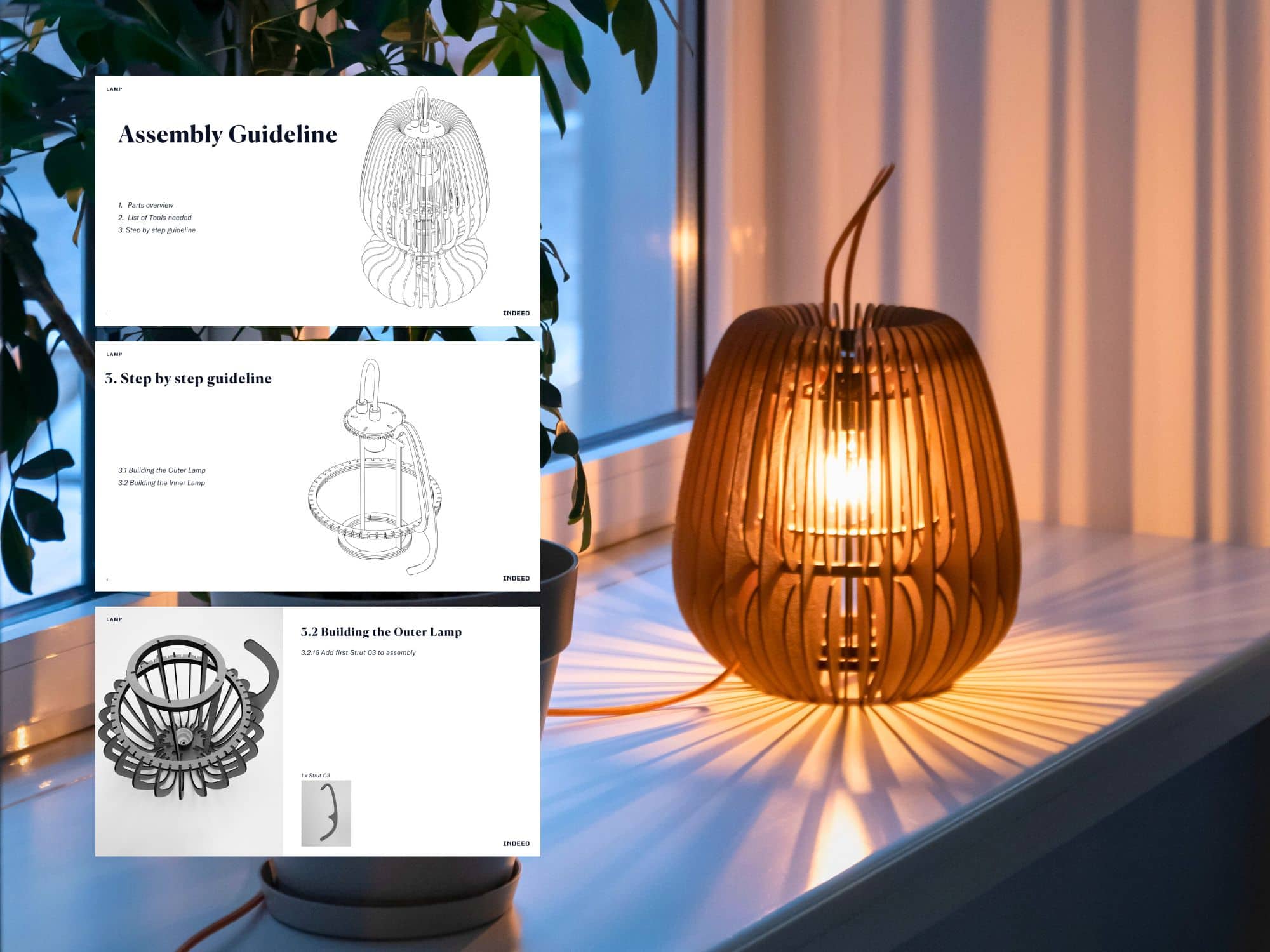

Design features of the Fab City lamp

- Modularity and adaptability: The Shift Light can be used as a table lamp, floor lamp, ceiling lamp, or wall lamp. The brightness can be adjusted by simply pulling the lamp head up or down. Thanks to an integrated cable system, the lamp can also be used as a ceiling lamp or in a group arrangement.

- Material diversity: The lamp’s slats can be made from various materials such as recycled plastic, plywood, acrylic glass, or cardboard. The parametric nature of the design makes it easy to adjust material thicknesses and types.

- Sustainability: The construction does not require adhesives, which makes repair and adjustment easy. Individual slats can be easily replaced to change the design or lighting effect.

- Open-source approach: Shift Light is developed as open-source hardware, which means that construction plans and instructions are publicly available and the license allows free use and adaptation of these plans. This enables FabLabs and individuals worldwide to replicate the lamp and participate in its development.

Motivation

LOCILAMP demonstrates how thoughtful design and open production processes lead to sustainable, adaptable products that can be manufactured locally and shared globally. The first iteration, Shift-Light, from the INTERFACER project in cooperation with Indeed Innovation, is already available as open source. The LOCILAMP repository will also be published here once the redesign is complete.

Local and digital

The New Production Institute subproject at Helmut Schmidt University (HSU) is developing a comprehensive model for distributed production: user requirements are translated into concrete product solutions, digital interfaces are implemented, and the entire production process is mapped in prototype form. This provides tangible evidence of how local and digital value creation networks can be made sustainable for the future.

Community & Practice

As a practical partner, Tchibo contributes its expertise in customer engagement and product development, while HSU takes care of modeling, planning, and implementation of the prototypical distributed production.

Key Points

Our goal is the comprehensive provision and further development of the project results. We promote the use of our findings and developments by third parties in the following ways:

- Open Source Ecosystem: We rely on open source software and hardware and also license our project developments as open source in widely used repositories. This expressly enables and promotes commercial exploitation by third parties.

- Transparent technology: Technical and IT developments are documented in detail and made publicly available to ensure that third parties can study, adapt, and use them.

- Infrastructure & standards: We build on the Fab City Operating System and ensure compatibility with relevant standards and EU requirements (e.g., Digital Product Passport).

- Knowledge transfer: Scientific findings are processed in such a way that they can be transferred and serve as a starting point for other industries.

- Networking & exchange: We actively share project results and experiences in regional and national scientific and economic networks, as well as in stakeholder workshops with chambers, associations, and companies.

- Communication & reach: Best practices are tailored to specific target groups and disseminated via various media channels as well as existing platforms and networks.

- Sustainable cooperation: We actively initiate and strengthen partnerships and cooperation for future projects and further developments.

Key results

In the project, we achieved concrete results that enable local, circular, and distributed production. These include the involvement of test customers in product development, the creation of a digital prototype for a product passport, and the distributed production of physical lighting prototypes on an open-source basis. Our work culminated in the publication of recommendations for action for distributed production.

Subproject A (HSU) defined requirements and interfaces, developed a process model for distributed production, tested physical prototypes in build workshops, simulated the value creation process in FCOS, and conducted stakeholder workshops to validate the results.

Subproject B (Tchibo) provided customer feedback on circular products, a fully documented luminaire design, a carbon footprint and lifecycle analysis, a certification report for circular/distributed production, and a visual representation of the value creation process.

Project consortium

Fab-Dictionary

Circular Design

Circular design means designing products so that they can be easily repaired, reused, or recycled. The aim is to keep resources in circulation for as long as possible. This includes, for example, modular construction, easily detachable connections, or the use of recyclable materials.

Digitaler Produktpass (DPP)

A digital product passport is a digital file that contains information about a product’s origin, materials, reparability, recyclability, and carbon footprint. It creates transparency along the value chain and will become mandatory in many industries in the future. LOCILAMP is testing the first prototype implementations of a DPP for open-source hardware designs. More on this in the Interfacer project.

Fab City Operating System (FCOS)

The Fab City Operating System is a digital infrastructure for local production: it helps to collect, exchange, and utilize production data—e.g., for the digital product passport or for visualizing value creation networks. LOCILAMP uses FCOS to simulate and control the distributed manufacturing process. More information can be found in the Interfacer project.

Project title & duration

- LOCILAMP – The Fab City Lamp. Testing local, circular, and distributed production

- Funding amount: ~ €330,000

- Oct 2024 – Mar 2026