Hamburg as a model city for the circular economy

Circular economy – an economic model in which existing materials are shared, repaired, and recycled for as long as possible in order to extend the life cycle of a product and maximize its value.

Finite resources and global challenges

The Earth’s natural resources are limited, and rising consumption and a growing global population are exacerbating environmental problems. Global resource depletion has tripled since 1970, while the world’s population has more than doubled over the same period. According to forecasts, the population will exceed nine billion by 2050, with two-thirds living in cities. These developments present urban centers with the key task of using resources efficiently and establishing sustainable economic systems.

Our research examines how cities can put the principles of the circular economy into practice. The focus is on innovative forms of urban production, local cycles, sustainable product design, and the promotion of bottom-up value creation. Repairability, recycling technologies, and new business models can conserve resources, create jobs, and improve the quality of life in urban areas.

Hamburg serves as an exemplary location for demonstrating the opportunities offered by an urban circular economy. The approach combines ecological responsibility, economic efficiency, and social participation—in line with the goals of the EU Green Deal.

Circular economy as a sustainable alternative for cities

The prevailing linear economic model of “produce – use – dispose” leads to considerable losses of raw materials and increasing environmental pollution. Products are transported globally and incinerated or landfilled after use, resulting in the loss of valuable resources. This system is therefore also referred to as the throwaway economy.

The circular economy aims to keep materials and products in the economic cycle for as long as possible, avoid waste, and use resources efficiently. Cities such as Hamburg can play a pioneering role through urban production, local cycles, and digital technologies.

EU - Circular Economy Action Plan

The EU Green Deal fully supports this transformation. The aim is to increase resource efficiency, halt biodiversity loss, and make Europe climate neutral by 2050. Initiatives such as the Circular Economy Act and the second Circular Economy Action Plan promote the reuse of materials, the reparability of products, and the creation of a single market for secondary raw materials (environment.ec.europa.eu). Products should be usable for longer, repairable, and remain in the EU to avoid waste exports (environment.ec.europa.eu).

Hamburg as a model city for the circular economy

Hamburg offers ideal conditions for implementing the principles of the circular economy. Through urban production, the city can manufacture goods directly for local consumption, minimize transport routes, and promote economic and ecological sustainability. Digitalization and citizen participation open up low-threshold access to production and recycling technologies, enabling innovative business models and local jobs.

The city can leverage a dense network of businesses, research institutions, and civil society initiatives to establish local cycles. Repairability, sustainable product design, and recycling technologies form the basis for an urban circular economy that aligns with the goals of the EU Green Deal (environment.ec.europa.eu).

Bottom-up economy and participatory value creation

Globalization and digital networking are promoting new value creation patterns: in the bottom-up economy, production and consumption are merging, while collaborative structures and open processes are shaping service provision. Cities such as Hamburg can use these models to promote participatory economic forms and actively involve the local population.

Repairability and sustainability

Promoting repairability is a key lever for resource conservation and climate protection. Since 2021, the EU Ecodesign Directive has stipulated that large electrical appliances such as refrigerators, washing machines, and televisions must be easier to repair. Newer regulations from the EU Green Deal, such as the Ecodesign for Sustainable Products Regulation (2024) and the Directive on repair of goods (2024), further strengthen product longevity and the circular economy (environment.ec.europa.eu).

The EU’s goal: to double the circular economy rate in Europe from the current 12% to 24% by 2030 (environment.ec.europa.eu).

Vision of an urban circular economy

Hamburg can serve as a model city for how urban production, local cycles, and bottom-up economies can be successfully combined. Shorter supply chains, sustainable production, and citizen participation generate economic, ecological, and social benefits. The city thus becomes a living laboratory for the circular economy, putting the goals of the EU Green Deal into practice and promoting innovation, jobs, and democratic participation (

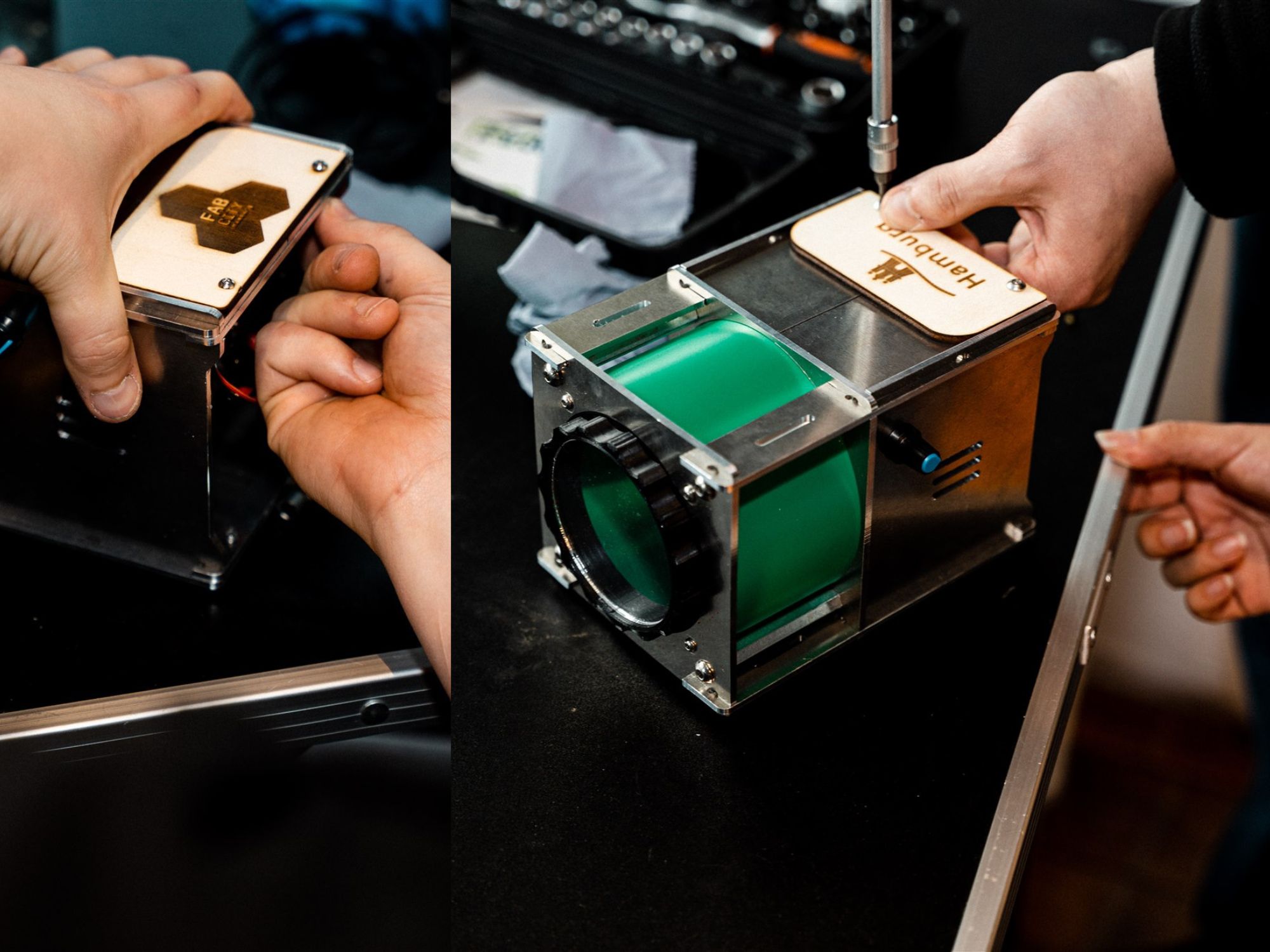

The OpenLab Microfactory concept

The OpenLab Microfactory describes a factory concept for the local and recyclable production of high-quality products (of varying complexity and vertical integration) with the involvement of citizens in the production process. As a small-scale, minimally invasive, and maximally modular factory unit, the OpenLab Microfactory uses open-source hardware machine tools (such as the OpenLab Starter Kit) as well as open-source software solutions for collecting, processing, and visualizing process data, such as energy consumption or the operating states of machines. The aim is to achieve data-based operation of the microfactory. This data helps to make statements about the use of resources and materials and is provided openly and transparently to show the ecological impact of the Microfactory.

Exhibition by OpenLab Microfactory at the Pop-Up Circular Hub in Jupiter (2024-2025), the former Karstadt-Sport building in the center of Hamburg.

Circular open source coffee grinder: GitHub – satshas/Coffee-Grinder: An Open Source Coffe Grinder made with a Pop-up Factory and Open Hardware Fab Lab Machines.

Dashboard display showing the energy consumption of the open source machine tools in the OpenLab Microfactory.

Opencyclone – produced using a 3D printer in the OpenLab Microfactory – Currently on display at FABRIC (Große Bleichen 22, Hamburg).

Products manufactured in the OpenLab Microfactory using 3D printers, CNC milling machines, and laser cutters, including a mixer (re-Mix Blender) and salt and pepper mills.

OpenLab Microfactory auf der Future of Making Conference + Expo im März 2023. Links ist Daniele Ingrassia, Gründer und CEO von Inmachines (OpenLab Starter Kit).