From March 22 to 25, our open source building workshop was successfully held at ENIT in Tunis to jointly build open source hardware. Funded by the German Federal Ministry of Education and Research, the Tunisian partners successfully built open-source machines for local use in the textile industry under the guidance of Helmut Schmidt University.

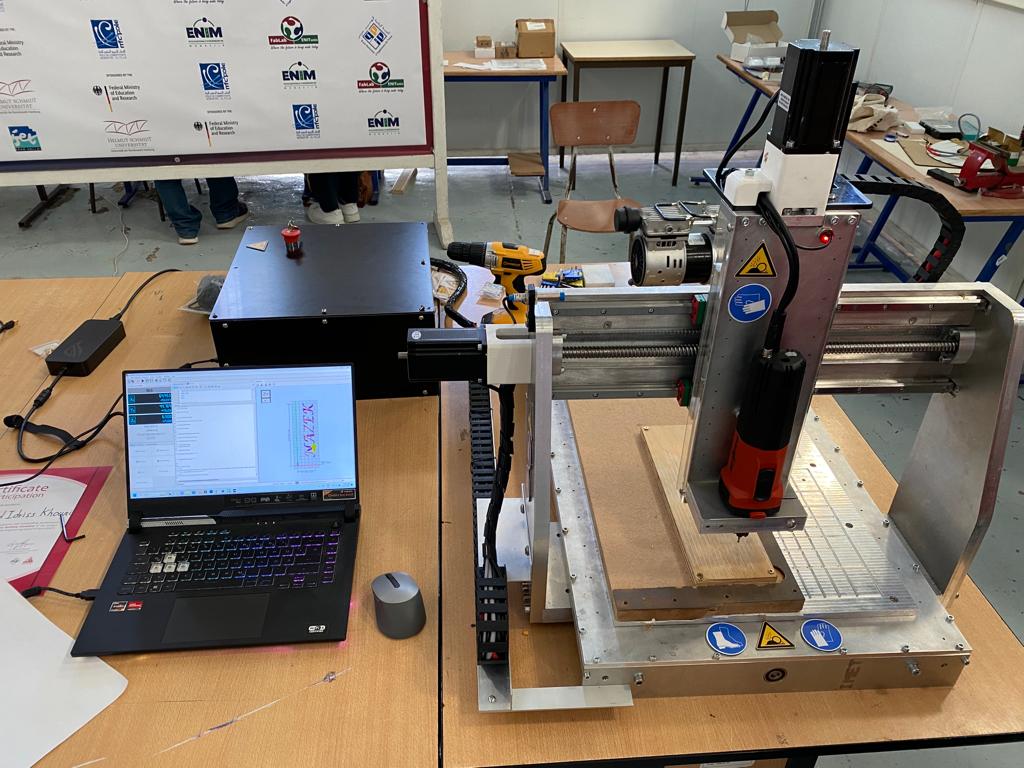

We developed 3 3dprinters, 1 CNC milling machine and 1 Laser cutter with participants from ENIT, ENIM, ISET and mfc pole. Open Source Hardware Experts of InMachines Ingrassia GmbH worked as coaches within the workshop. “Not only did we complete the five planned machines, which in itself is a great success, but in addition, the participants expressed that they now feel better able to apply the knowledge they learned to building and repairing other machines,” said project leader Dr. Juan Manuel Luyando Grados.

The workshop took place as part of the PISWI research project, which is funded by the BMBF. The project is a follow-up of the first PISWI project that has been implemented in 2019. The research cooperation is targeting the potential of open production spaces for technological empowerment and innovation based on Open-Source Appropriate Technology (OSAT).

The execution of the project and the implementation of the open production space is done with local actors from research and industry in the Tunisian textile sector. The research network is coordinated by the Laboratory of Production Engineering/ New Production Institute of Helmut Schmidt University, the local project management is conducted by the National Engineering School of Tunis (ENIT) – Tunis el Manar and the project implementation partners are the National Engineering School of Monastir (ENIM), the Institut Supérieur des Études Technologieques de Ksar Hellal (ISET) and the Monastir-El Fejja (la Manouba) competitiveness cluster (mfcpole).

More information on the project via https://newproductioninstitute.de/places-of-incubovation and https://madeintunisia.org/

Photos by FabLab ENIT